| 명백한 다공성: | ≤ 22% | 밀도: | 2.2-2.4 g/cm3 |

|---|---|---|---|

| 목: | 높은 알루미나 벽돌 | 연화 온도: | ≥1400 00 |

| 마모 저항: | 높은 | 서비스 온도: | 높은 |

| 부식 저항: | 높은 | 하중 하에서 굴절: | ≥ 1520 ℃ |

| 애플리케이션: | 고온 용광로 안감 | 온도: | 1700-1800 00 |

| 영구적 인 선형 변화: | 낮은 | 알칼리 저항: | 높은 |

| CCS 강도: | 45 | 산성 저항: | 높은 |

| 표면: | 매끄러운 | ||

| 강조하다: | 전기 활 오븐용 고 알루미나 난방 벽돌,48-90% Al2O3 알루미나 실리카 화면 벽돌,230x114x65mm 높은 알루미나 난방 벽돌 |

||

고품질 48-90% Al2O3 알루미나 실리카 불 벽돌 230*114*65mm 전기 아크 오븐 지붕을 위한 고 알루미나 불소연 벽돌

고 알루미나 불화성 벽돌

고 알루미나 벽돌은 알루미노 실리케이트 불탄소 제품으로 알루미늄 산화물 (Al2O3) 함량이 48% 이상입니다. 중립 불탄소 재료에 속합니다.고 알루미나 함량이 있는 바우크사이트 또는 다른 원료의 형성 및 연화로 생성됩니다.1770 °C 이상 높은 열 안정성 및 불 저항성. 좋은 찌꺼기 저항성을 가지고 있으며 철강 제조 전기 오븐, 유리 오븐, 시멘트 회전 오븐 등을 부착하는 데 사용됩니다.

높은 부하 부드럽고 낮은 크립 높은 알루미나 벽돌은 특수급 바우크사이트, 녹은 코룬드 및 녹은 뮬리트로 만들어진 고품질의 불투명 물질입니다.이 제품은 작은 고온 크립의 장점이 있습니다., 강한 경화 저항성, 좋은 열 충격 안정성 등 큰 및 중형 뜨거운 고화전용으로 적합합니다.

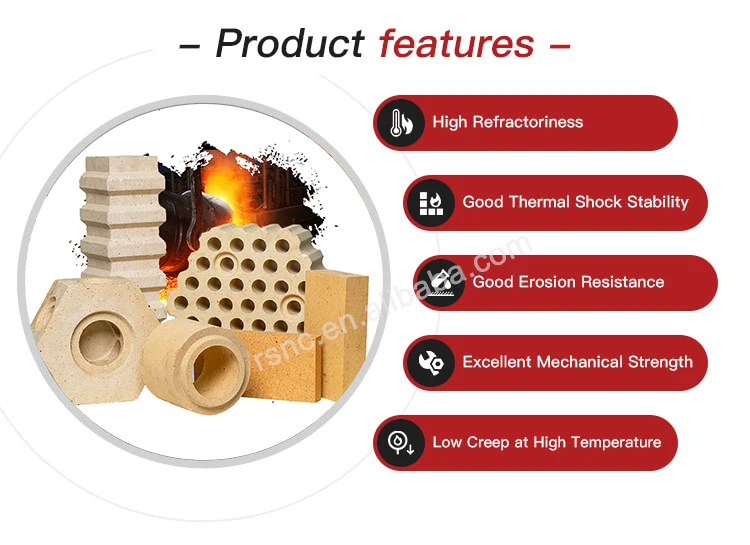

고 알루미나 불소연 벽돌 장점

1. 높은 불조절성;

2고온 강도

3높은 열 안정성

4중립 불탄소;

5산성 및 기초 찌꺼기 부식에 대한 좋은 저항성;

6부하 하에서의 높은 굴절성;

7. 높은 온도 크립 저항;

8낮은 겉보기 포러스;

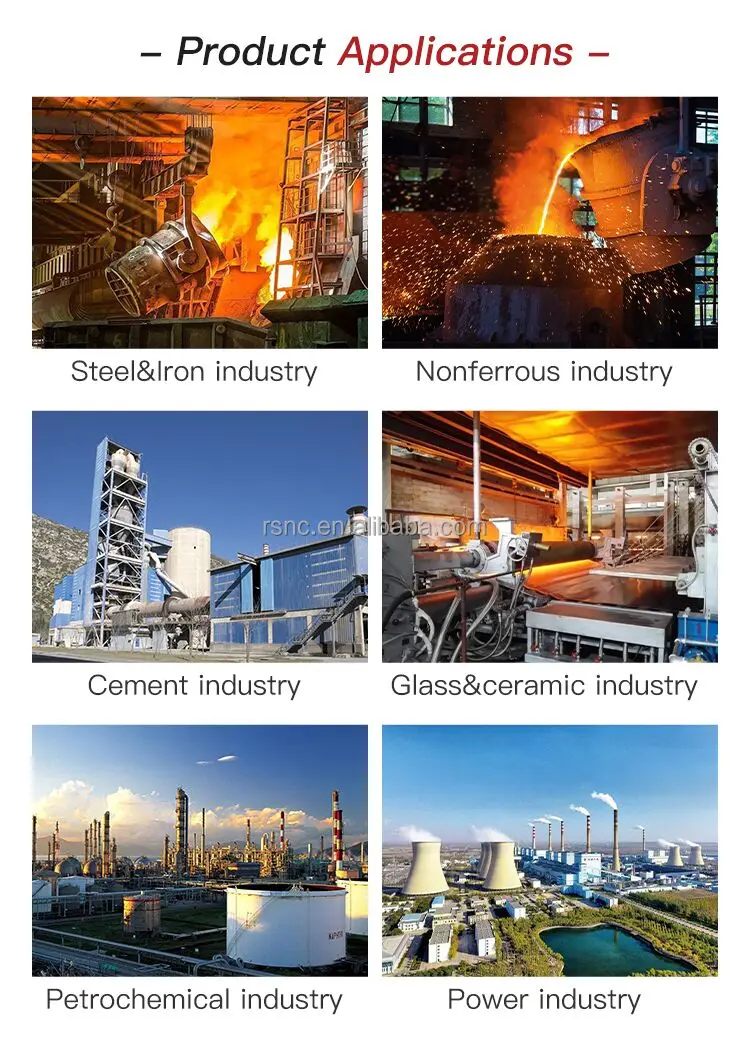

고 알루미나 불소연 벽돌 응용

고온 기술 분야에서 기본 재료로서, 고 알루미나 벽돌은 시멘트, 유리 건축 재료, 철강 용조, 석유화학 및 기타 산업에서 널리 사용됩니다.고 알루미나 벽돌을 위한 고온 산업용 오븐에는 고온 오븐이 포함됩니다., 뜨거운 높은 오븐, 전기 오븐, 높은 오븐, 반향 오븐 및 회전 오븐 부리. 또한 고 알루미나 벽돌은 개방형 화면 재생 그리드 벽돌로 처리 될 수 있습니다.붓기 시스템용 소켓 벽돌, 노즐 벽돌, 등 산업 오븐의 요구 사항에 따라.

고 알루미나 불소연 벽돌 물리적 화학 지수:

| 품목/등급 | 화면 점토 벽돌 | 고 알루미나 벽돌 | ||||||

| SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 | |

| AL2O3% (≥ | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3% (≤) | 2.5 | 2.5 | 2 | 2 | 2 | 2 | 2 | 2 |

| 반열성 (SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| 부하의 반열성, 0.2MPa, °C (≥) | 1250 | 1300 | 1360 | 1420 | 1450 | 1480 | 1530 | 1600 |

| 겉으로 보이는 엽기성 (%) | 22-26 | 20~24 | 20-22 | 18-20 | 20~23 | 20~23 | 20-22 | 18-20 |

| 대량 밀도 (g/cm3) | 1.9-20 | 1.95-2.1 | 20.1-22 | 2.15-2.22 | 2.25-2.4 | 20.3-25 | 2.4-26 | 2.5-27 |

| 냉압 강도,MPa (≥) | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

| 벽돌 표준 크기 | |||||

| 스플리트 스트레이트 L×W×H(mm) |

SPLIT L×W×H(mm) |

ARCH L×W×H(mm) |

빗자루 L×W×H(mm) |

타일 L×W×H(mm) |

다른 형태 |

| 230 × 114 × 65 | 230 × 114 × 25 | 230×114×65/45 | 230×114×65/45 | 230×230×38 | 열쇠 벽돌 |

| 230 × 114 × 75 | 230 × 114 × 32 | 230×114×65/55 | 230×114×65/55 | 230×230×50 | 굽은 벽돌 |

| 230 × 114 × 37 | 230 × 114 × 75/45 | 220×114×75/45 | 230×230×65 | 비누 | |

| 230 × 114 × 50 | 230×114×75/55 | 220×114×75/55 | 230×230×75 | 체크 | |

| ≤10 | 230×114×75/65 | 220×114×75/65 | 목 | ||

| 톱니 | |||||

| 적용 | 철강 오븐, 유리 오븐, 나트륨 실리케이트 오븐, 세라믹 셔틀 오븐, 시멘트 회전 오븐, 고화장, 전기 오븐, 고화장 및 울림 오븐 | ||||

| 우리는 또한 고객의 그림과 요구 사항에 따라 벽돌을 만들 수 있습니다. | |||||

담당자: Mr. Pika

전화 번호: 86-13838387996

팩스: 86-0371-56010932